Magnetic circuit production of amorphous nanocrystalline alloys is also possible

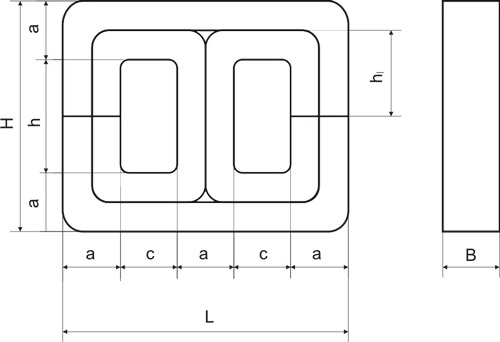

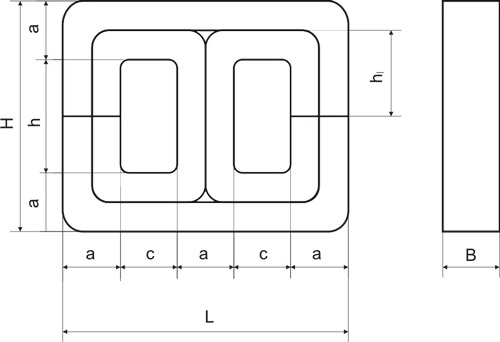

Standard Parameters and Dimensions

Magnetic circuits are produced according to Drawing 1, Table 1 and 2 out of hoop steel:

- of Grade 3413, ÃÎÑÒ 21427.1-83, with a thickness of 0.35 mm for power line frequency of 50 Hz;

- of Grade 3422, ÃÎÑÒ 21427.4-78, with a thickness of 0.15 mm for power line frequency of 400 Hz;

- Chamfering 0.1õ450 is allowed on core rod butt ends;

- Outer core rod displacement relative to each other for the value Ê in defined position of middle core rod is allowed.

Magnetic circuit surfaces except specified 3, 2 are covered with enamel ÝÝÏ-140 of light grey colour. Use of enamels of other brands is allowed.

Table 1

| Magnetic circuit reference designation |

Ê |

a |

h |

h1 |

c |

L*

| H*

| B |

Rmax

| Magnetic circuit weight, kg |

| Nomin. |

Extr. dev. |

Rmax |

Nomin. |

Nomin. |

Nomin. |

Extr. dev. |

| ÒË12,5õ20-25-0,35-50 |

+0,3 |

12,5 |

+0,24

-0,43 |

25,0 |

12,5 |

25 |

87,5 |

50,0 |

20 |

+0,84 |

1,2 |

0,485 |

| ÒË12,5õ20-29-0,35-50 |

29,0 |

12,5 |

54,0 |

0,505 |

| ÒË12,5õ20-33-0,35-50 |

33,0 |

16,5 |

58,0 |

0,525 |

| ÒË12,5õ20-38,5-0,35-50 |

38,5 |

16,5 |

63,6 |

0,550 |

| ÒË12,5õ20-440,35-50 |

44,0 |

22,0 |

69,0 |

0,580 |

| |

| ÒË16õ25-32-0,35-50 |

+0,5 |

16,0 |

+0,24

-0,43 |

32,0 |

16,0 |

32 |

112 |

64,0 |

25 |

+0,84 |

1,3 |

1,000 |

| ÒË16õ25-37-035-50 |

37,0 |

16,0 |

69,0 |

1,050 |

| ÒË16õ25-42-0,35-50 |

42,0 |

|

74,0 |

1,100 |

| ÒË16õ25-49-0,35-50 |

49,0 |

21,0 |

81,0 |

1,180 |

| ÒË16õ25-56-0,35-50 |

56,0 |

28,0 |

88,0 |

1,260 |

| |

| ÒË20õ32-40-0,35-50 |

+0,7 |

20 |

+0,28

-0,52 |

40,0 |

20,0 |

40 |

140 |

80,0 |

32 |

+1,0 |

1,4 |

1,960 |

| ÒË20õ32-47-0,35-50 |

47,0 |

20,0 |

87,0 |

2,070 |

| ÒË20õ32-54-0,35-50 |

54,0 |

27,0 |

94,0 |

1,170 |

| ÒË20õ32-62-0,35-50 |

62,0 |

27,0 |

102,0 |

2,320 |

| ÒË20õ32-70-0,35-50 |

70,0 |

35,0 |

110,0 |

2,480 |

| |

| ÒË25õ40-50-0,35-50 |

+,9 |

25 |

+0,28

-0,52 |

50,0 |

25,0 |

50 |

175 |

100,0 |

40 |

+1,0 |

1,5 |

3,82 |

| ÒË25õ40-58-0,35-50 |

58,0 |

25,0 |

108,0 |

3,96 |

| ÒË25õ40-66-0,35-50 |

66,0 |

33,0 |

116,0 |

4,15 |

| ÒË25õ40-77-0,35-50 |

77,0 |

33,0 |

127,0 |

4,45 |

| ÒË25õ40-88-0,35-50 |

88,0 |

44,0 |

138,0 |

4,75 |

| |

| ÒË32õ40õ64-0,35-50 |

+1,0 |

32 |

+0,34

-0,62 |

64 |

32 |

64 |

224 |

128 |

40 |

+1,0 |

|

6,10 |

| ÒË32õ40õ74-0,35-50 |

74 |

32 |

138 |

6,45 |

| ÒË32õ40õ84-0,35-50 |

84 |

42 |

148 |

6,80 |

| ÒË32õ40õ97-0,35-50 |

97 |

42 |

161 |

7,25 |

| ÒË32õ40õ110-0,35-50 |

110 |

55 |

174 |

7,65 |

Table 2

| Magnetic circuit reference designation |

Ê |

a |

h |

h1 |

c |

L* |

H* |

B |

Rmax |

Magnetic circuit weight, kg |

| Nomin. |

Extr. dev. |

Nomin. |

Nomin. |

Nomin. |

Nomin. |

Extr. dev. |

| ÒË5õ10-14-0,15-400 |

0,4 |

5,0 |

+0,16 -0,30 |

14 |

7 |

14 |

43,0 |

24 |

10,0 |

+0,58 |

0,5 |

0,049 |

| ÒË5õ10-16-0,15-400 |

16 |

7 |

26 |

0,051 |

| ÒË5õ10-18-0,15-400 |

18 |

9 |

28 |

0,053 |

| ÒË5õ10-21-0,15-400 |

21 |

9 |

31 |

0,057 |

| ÒË5õ10-24-0,15-400 |

24 |

12 |

34 |

0,066 |

| |

| ÒË6,5õ10-16-0,15-400 |

0,4 |

6,5 |

+0,20 -0,36 |

16 |

8 |

16 |

51,5 |

29 |

10,0 |

+0,58 |

0,6 |

0,072 |

| ÒË6,5õ10-18-0,15-400 |

18 |

8 |

31 |

0,075 |

| ÒË6,5õ10-20-0,15-400 |

20 |

10 |

33 |

0,078 |

| ÒË6,5õ10-23-0,15-400 |

23 |

10 |

36 |

0,083 |

| ÒË6,5õ10-26-0,15-400 |

26 |

13 |

39 |

0,087 |

| |

| ÒË8õ12,5-18-0,15-400 |

0,4 |

8,0 |

+0,20 -0,36 |

18 |

9 |

18 |

60, |

34 |

12,5 |

+,70 |

0,7 |

0,120 |

| ÒË8õ12,5-21-0,15-400 |

21 |

9 |

37 |

0,151 |

| ÒË8õ12,5-24-0,15-400 |

24 |

12 |

40 |

0,163 |

| ÒË8õ12,5-28-0,15-400 |

28 |

12 |

44 |

0,172 |

| ÒË8õ12,5-32-0,15-400 |

32 |

16 |

48 |

0,170 |

| |

| ÒË10õ16-20-0,15-400 |

0,4 |

10,0 |

+0,20 -0,36 |

20,0 |

10,0 |

20 |

70,0 |

40,0 |

16 |

+0,7 |

0,8 |

0,240 |

| ÒË10õ16-23-0,15-400 |

23,0 |

10,0 |

43,0 |

0,250 |

| ÒË10õ16-26-0,15-400 |

26,0 |

13,0 |

46,0 |

0,260 |

| ÒË10õ16-31-0,15-400 |

31,0 |

13,0 |

51,0 |

0,275 |

| ÒË10õ16-36-0,15-400 |

36,0 |

18,0 |

56,0 |

0,290 |

| |

| ÒË12,5õ20-25-0,15-400 |

0,5 |

12,5 |

+0,24 -0,43 |

25,0 |

12,5 |

25 |

87,5 |

50 |

20 |

+0,84 |

0,9 |

0,470 |

| ÒË12,5õ20-29-0,15-400 |

29,0 |

12,5 |

54 |

0,490 |

| ÒË12,5õ20-33-0,15-400 |

33,0 |

16,5 |

58 |

0,510 |

| ÒË12,5õ20-38-0,15-400 |

38,5 |

16,5 |

63,5 |

0,525 |

| ÒË12,5õ20-44-0,15-400 |

44,0 |

22,0 |

69 |

0,560 |

| |

| ÒË16õ25-32-0,15-400 |

0,6 |

16,0 |

+0,24

-0,43 |

32,0 |

16,0 |

32 |

112 |

64,0 |

25 |

+0,84 |

1,0 |

0,970 |

| ÒË16õ25-37-0,15-400 |

37,0 |

16,0 |

69,0 |

1,020 |

| ÒË16õ25-42-0,15-400 |

42,0 |

21,0 |

74,0 |

1,070 |

| ÒË16õ25-49-0,15-400 |

49,0 |

21,0 |

81,0 |

1,140 |

| ÒË16õ25-56-0,15-400 |

56,0 |

28,0 |

88,0 |

1,220 |

| |

| ÒË20õ32-40-0,15-400 |

0,7 |

20 |

+0,28

-0,52 |

40,0 |

20,0 |

40 |

140 |

80,0 |

32 |

+1,0 |

1,1 |

1,900 |

| ÒË20õ32-47-0,15-400 |

47,0 |

20,0 |

87,0 |

2,000 |

| ÒË20õ32-54-0,15-400 |

54,0 |

27,0 |

94,0 |

2,100 |

| ÒË20õ32-62-0,15-400 |

62,0 |

27,0 |

102,0 |

2,250 |

| ÒË20õ32-70-0,15-400 |

70,0 |

35,0 |

110,0 |

2,400 |

| |

| ÒË25õ40-50-0,15-400 |

+0,8 |

25 |

+0,28

-0,52 |

50,0 |

25,0 |

50 |

175 |

100,0 |

40 |

1,0 |

1,2 |

3,700 |

| ÒË25õ40-58-0,15-400 |

58,0 |

25,0 |

108,0 |

3,850 |

| ÒË25õ40-66-0,15-400 |

66,0 |

33,0 |

116,0 |

4,00 |

| ÒË25õ40-77-0,15-400 |

77,0 |

33,0 |

127,0 |

4,400 |

| ÒË25õ40-88-0,15-400 |

88,0 |

44,0 |

138,0 |

4,60 |

| |

| ÒË32õ40-64-0,15-400 |

+1,0 |

32 |

+0,34-0,62 |

64 |

32 |

64 |

224 |

128 |

40 |

+1,0 |

1,3 |

5,900 |

| ÒË32õ40-74-0,15-400 |

74 |

32 |

138 |

6,250 |

| ÒË32õ40-84-0,15-400 |

84 |

42 |

148 |

6,600 |

| ÒË32õ40-97-0,15-400 |

97 |

42 |

161 |

7,000 |

| ÒË32õ40-110-0,15-400 |

110 |

55 |

174 |

7,600 |

1.2. Magnetic circuit reference designation consists of initial letters of words "three-phase" (T), "strap" (Ë) and figures, which designate accordingly rod dimensions, aperture height, band thickness and frequency, at which magnetic circuit is inspected for compliance with requirements of existing standard.

Specification

2.1.1 General requirements

2.1.1. Magnetic circuit should be produced according to the requirements of existing standard.

2.1.2. Materials and semifinished goods used during magnetic circuit production should have appropriate documentation, which confirms their operability in conditions at least equal to the requirements of existing standard.

2.2. Design requirements

2.2.1. Magnetic circuits design and dimensions should comply with Drawing 1 and Table 1 and 2.

2.2.2. Magnetic circuit surface should be without any dirt marks, dints and other mechanical damages and also without corrosion marks.

2.2.3. Magnetic circuits should be monolithic, butt end opening is not allowed.

Note: 1. Gaps between plates are allowed in core mass.

2. Plates recess by width up to 5% of rod thickness is allowed.

3. Glueing of plates, which are separated during magnetic circuit butt end depreservation, with ÁÔ-4 glue according to ÃÎÑÒ 12127-74 or equivalent is allowed by consumer.

2.2.4. Magnetic circuit weight should comply with the data specified in Table 1 and 2.

Required Electrical Parameters

2.3.1. Excitation current value and power loss of magnetic circuits should comply with data specified in Table 3 for magnetic circuits with frequency of 50 Hz and in Table 4 for magnetic circuits with frequency of 400 Hz.

Table 3

| Magnetic circuit dimension type |

Induction,,

Wb/m2 |

Current value, A, not more than |

Power loss, W, not more than |

Impressed voltage, phase, V |

Winding turn number W1=W2 |

Winding wire diameter,

mm |

| ÒË12,5õ20-25 |

1,5 |

3õ0,036 |

- |

73,5 |

950 |

0,2 |

| ÒË12,5õ20-29 |

3õ0,038 |

| ÒË12,5õ20-33 |

3õ0,040 |

| ÒË12,5õ20-38,5 |

3õ0,042 |

| ÒË12,5õ20-44 |

3õ0,044 |

| |

| ÒË16õ25-32 |

1,5 |

3õ0,070 |

- |

73,5 |

591 |

0,29 |

| ÒË16õ25-37 |

3õ0,073 |

| ÒË16õ25-42 |

3õ0,076 |

| ÒË16õ25-49 |

3õ0,081 |

| ÒË16õ25-56 |

3õ0,086 |

| |

| ÒË20õ32-40 |

1,5 |

3õ0,130 |

5,0 |

73,5 |

370 |

0,44 |

| ÒË20õ32-47 |

3õ0,137 |

5,2 |

| ÒË20õ32-54 |

3õ0,144 |

5,5 |

| ÒË20õ32-62 |

3õ0,153 |

5,8 |

| ÒË20õ32-70 |

3õ0,162 |

6,1 |

| |

| ÒË25õ40-50 |

1,45 |

3õ0,215 |

|

73,5 |

245 |

0,8 |

| ÒË25õ40-58 |

3õ0,225 |

| ÒË25õ40-66 |

3õ0,235 |

| ÒË25õ40-77 |

3õ0,250 |

| ÒË25õ40-88 |

3õ0,267 |

| |

| ÒË32õ40õ64 |

|

|

|

73,5 |

198 |

1,0 |

| ÒË32õ40õ74 |

| ÒË32õ40õ84 |

| ÒË32õ40õ97 |

| ÒË32õ40õ110 |

Table 4

| Magnetic circuit dimension type |

Induction,

Wb/m2 |

Current value, A, not more than |

Power loss, W, not more than |

Impressed voltage, phase, V |

Winding turn number W1=W2 |

Winding wire diameter,

mm |

| ÒË5õ10-14 |

1,4 |

3õ0,058 |

- |

73,5 |

655 |

0,11 |

| ÒË5õ10-16 |

3õ0,060 |

| ÒË5õ10-18 |

3õ0,062 |

| ÒË5õ10-21 |

3õ0,065 |

| ÒË5õ10-24 |

3õ0,068 |

| |

| ÒË6,5õ10-16 |

1,4 |

3õ0,080 |

- |

73,5 |

508 |

0,15 |

| ÒË6,5õ10-18 |

3õ0,082 |

| ÒË6,5õ10-20 |

3õ0,084 |

| ÒË6,5õ10-23 |

3õ0,07 |

| ÒË6,5õ10-26 |

3õ0,090 |

| |

| ÒË8õ12,5-18 |

1,4 |

3õ0,125 |

3,9 |

73,5 |

327 |

0,21 |

| ÒË8õ12,5-21 |

3õ0,130 |

4,1 |

| ÒË8õ12,5-24 |

3õ0,135 |

4,3 |

| ÒË8õ12,5-28 |

3õ0,140 |

4,6 |

| ÒË8õ12,5-32 |

3õ0,145 |

4,9 |

| |

| ÒË10õ16-20 |

1,4 |

3õ0,210 |

6,9 |

73,5 |

204 |

0,35 |

| ÒË10õ16-23 |

3õ0,217 |

7,2 |

| ÒË10õ16-26 |

3õ0,225 |

7,6 |

| ÒË10õ16-31 |

3õ0,232 |

8,2 |

| ÒË10õ16-36 |

3õ0,240 |

8,8 |

| |

| ÒË 12,5õ20-25 |

1,32 |

3õ0,290 |

11,8 |

73,5 |

139 |

0,51 |

| ÒË 12,5õ20-29 |

3õ0,300 |

12,4 |

| ÒË 12,5õ20-33 |

3õ0,310 |

13,1 |

| ÒË 12,5õ20-38,5 |

3õ0,320 |

13,8 |

| ÒË 12,5õ20-44 |

3õ0,330 |

14,6 |

| |

| ÒË16õ25-32 |

1,13 |

3õ0,330 |

17,8 |

73,5 |

102 |

0,64 |

| ÒË16õ25-37 |

3õ0,342 |

18,6 |

| ÒË16õ25-42 |

3õ0,355 |

19,5 |

| ÒË16õ25-49 |

3õ0,372 |

20,8 |

| ÒË16õ25-56 |

3õ0,390 |

22,2 |

| |

| ÒË20õ32-40 |

0,96 |

3õ0,380 |

24,4 |

73,5 |

76 |

0,80 |

| ÒË20õ32-47 |

3õ0,395 |

25,9 |

| ÒË20õ32-54 |

3õ0,410 |

27,5 |

| ÒË20õ32-62 |

3õ0,427 |

29,2 |

| ÒË20õ32-70 |

3õ0,445 |

31,0 |

| |

| ÒË25õ40-50 |

0,81 |

3õ0,450 |

33,6 |

73,5 |

57 |

0,93 |

| ÒË25õ40-58 |

3õ0,470 |

35,5 |

| ÒË25õ40-66 |

3õ0,490 |

37,5 |

| ÒË25õ40-77 |

3õ0,517 |

40,0 |

| ÒË25õ40-88 |

3õ0,545 |

42,0 |

| |

| ÒË32õ40õ64 |

0,73 |

3õ0,490 |

44,5 |

73,5 |

49 |

1,16 |

| ÒË32õ40õ74 |

3õ0,515 |

47,2 |

| ÒË32õ40õ84 |

3õ0,540 |

50,0 |

| ÒË32õ40õ97 |

3õ0,570 |

53,0 |

| ÒË32õ40õ110 |

3õ0,600 |

56,0 |