Multipurpose Non-Contact Loading Transformer

Purpose

Multipurpose non-contact loading transformer (ÓÁÊÒ) is designed for stepless control of commercial-frequency current and voltage during adjustment and alignment.

Multipurpose non-contact loading transformer (ÓÁÊÒ) is designed for stepless control of commercial-frequency current and voltage during adjustment and alignment.

ÓÁÊÒ is a single-phase transformer, consisting of two parts: stationary and moving. The moving part travels by means of screw-type device. There is split primary coil, which as a rule is connected to linear line voltage of 380 V, on the moving part.

There is changeable secondary winding on the stationary part.

Current and voltage control on secondary winding is performed by stepless change of magnetic flow by means of its redistribution during moving part travel.

It is possible to load different types of protections by primary current up to 6,000 A in a long-time mode by means of ÓÁÍÒ.

It is possible to get current up to 10,000 A for short term (within not more than 30 s).

Secondary winding is easy to remove off the core. This makes it possible to install necessary type of secondary winding depending on nature of the work performed. Secondary winding has three modifications:

Dear Friends!

Welcome to Our Website!

We offer for Your attention a wide range of magnetic circuits of types ÏË, ÏËÐ, ÏËÌ, ØË, ØËÌ, ØËÐ, ØËÎ, ØËÏ, ÎË and ÒË, three-phase transformers, multipurpose non-contact loading transformer etc.

Additional reference information and electrical engineering articles are also represented on the website in the Information section.

We are looking for effective cooperation! We are ready to answer all Your questions.

Yours Faithfully,

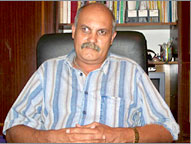

Andrey Ivanovich Glagolev,

The Director of Komplekt Transformator LLC

89 Kosmonavtov St.,

54031 Nikolaev, Ukraine

tel.: +38 (0512) 59-0316

fax: +38 (0512) 59-4958

mob. tel.: +38 (067) 173-6035

e-mail: info@glagolev.mk.ua

Nanocrystalline Soft Magnetic Alloy 5ÁÄÑÐ is a new material got by high speed melt-quench. Advantages of magnetic circuits made of this material are high induction at low coercive force, low losses for remagnetization at high frequencies, near-zero magnetostriction.

View more...

Multipurpose non-contact loading transformer (ÓÁÊÒ) is designed for stepless control of commercial-frequency current and voltage during adjustment and alignment.

Show all Transformers